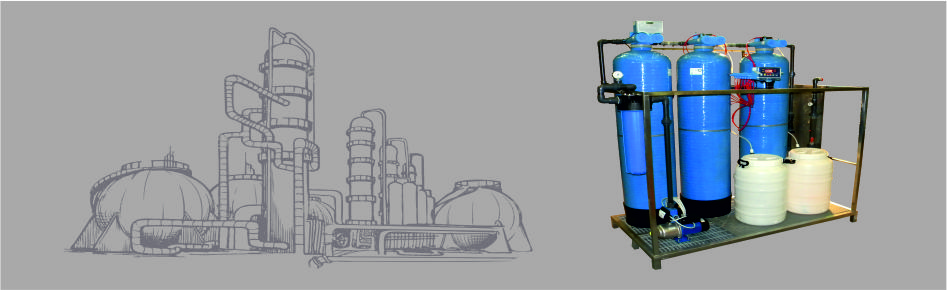

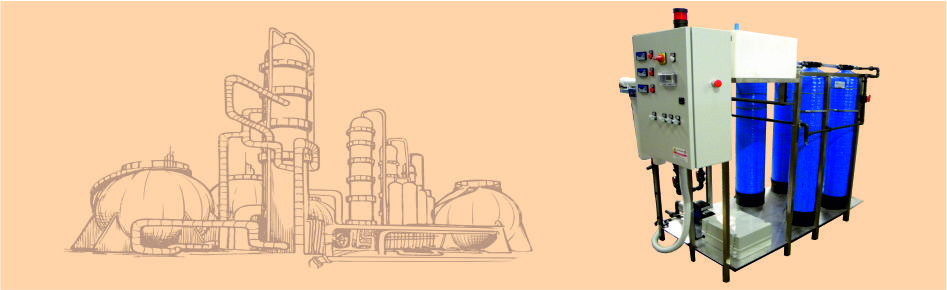

RO 160 EL - reverse osmosis purifier

|

| TECHNICAL FEEATURES | ||

| - operative pressure RO elements | bar 14-15 |

|

| - DAILY PRODUCTION | mc 1,6-2,1 |

|

| - min. feed pressure | bar 2,5 |

|

| - max feed pressure | bar 5,5 |

|

| - range of temperature water to be treated | °C 5-35 | |

| - HOURLY PRODUCTION | lt/h 160 | |

| - hidraulic connection | IN OUT DRAIN |

1" rilsan 10 rilsan 10 |

| - electric power | V AC 220 | |

| TECNICAL SPECIFICATION WATER TO BE TREATED | DIMENSIONS | |||

| TDS | ppm 500 | Lenght | max cm 53 | |

| Total hardness | °F 30 | Width | max cm 64 | |

| Iron | ppb 100 | Heigt | max cm 137 | |

| Manganese | ppb 5 | |||

| Chlor | ppm 0,1 | |||

| SDI | <5 | |||

| Total bacteria UFC/ml | <5 | |||

Optionals

Storage tanks outer PE HD, anti-dust system with a capacity of 200, 500, 1000 liters regulated by 2 magnetic sensors levels, one in principle (block) and a minimum (restart production) compatible with the PLC software. a third sensor can be installed to indicate a level below the minimum due to accidental stop of the plant.

Support for the storage tank. Stainless steel AISI 304, complete with support for lower repressurization pump (if required).

Function flow-meter, managed directly by the PLC, to achieve precision coverages. The external signal 'provided by a water meter Teflon-coated, the start of the machine is manual. The setting of the volume is easily adjustable using the keypad.

Repressurization pumps, both type BOOSTER low voltage complete switch and fast connection; either type pump in stainless steel, 220V power supply and control board for automatic operation.

UV sterilizer, made with outer jacket in AISI 304 or 316 on request, complete germicidal lamp, quartz and ballast power. 24 Vac power supply (power supply included).Can be installed on the water line produced or system recovery in pressure.

Anti-bacterial filter, composed of a 2-piece container, vessel inspection and transparent PE pleated cartridge, having a degree of 0.2 micron absolute filtration.

Operational characteristics of the control panel

Operational characteristics of the control panel

Direct management of the operational elements:

- solenoid valve input

- pump overpressure

- flushing system Programmable membrane (optional)

- Program protection through password

- Displaying messages and data on LCD display

- Timer programming function can only be set PC (optional)

print RO 90 160 250