UPW refiner - apparatus for the production of ultrapure water - grade 1

| QUALITY STANDARD | DIMENSIONS | |||

| ISO 3696 | grade 1 | Lenght | cm 44 | |

| ASTM | Type I | Width | cm 46 | |

| NCCLS | Type I | height | cm 52 | |

| EP/USP | conform | |||

| SPEC: EL: RESISTIVITY at 25°C | 18,2 MOhm.cm | dry Weight | kg 27 | |

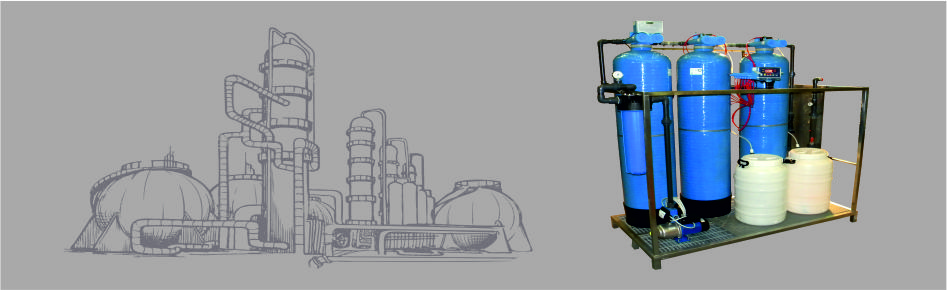

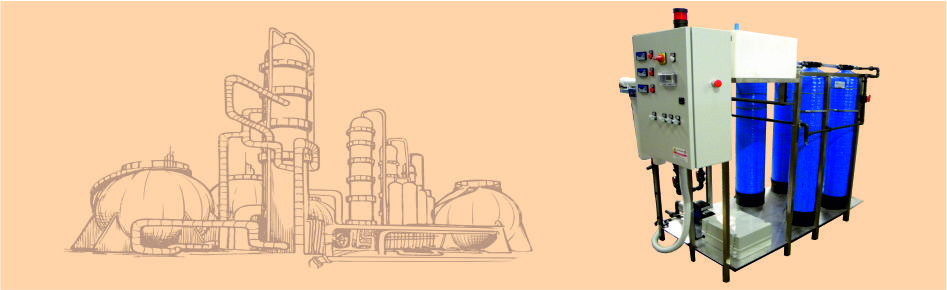

A fully automated apparatus to produce ultra pure water of grade 1

UPW refiner is a water purification system for the production of ultra pure water up to an electrical resistivity spec.di 18.2 Mohm.cm, suitable for analytical applications of high precision.

Everything under control

UPW refiner has a digital resistivimeter to monitor continuously the quality of the water produced, a PLC controller with a diplay for eil management control of operational functions and an LED panel that shows the states of the machine and any alarm .

Production of ultra pure water of grade 1 through 3 different types of purification

UPW refiner is powered by a source of demineralized water as OSMO LAB UPW 3, OSMO LAB 2, OSMO LAB 3 or any demineralizers of line gamma 3 capable of delivering water of at least grade 3 (pursuant to ISO 3696). UPW refiner is able to produce fully purified water from the saline (Spec electrical resistivity at 25 ° C - 18.2 MOhm.cm) and TOC levels are very low (<10 ppb), thanks to an automatically controlled recirculation and 3 different types of purification:

- Ion exchange resins type 1 and 2

- Photo oxidation with UV rays

- Microfiltration 0,2 micron antibacteria

Simplicity of operation and store of water always available

UPW refiner is very easy to use, since fully automatic in its duties and has a single button to levy placed on the front panel and provides a reservoir of water of 5 liters, which is restored after each use by the operator.

OPTIONALS

Flash sampling.

|

||

|

If you get there food with OSMO LAB UPW3, OSMO LAB 2 or OSMO LAB 3 in order to reduce the load times and therefore increase the efficiency of purification, you should insert the feeding tube of the tank lt 16 in pressure to be provided as an accessory (code 0000244).

|

||

print UPW refiner