RO 30 EL-TS demineralizer for laboratory and industry

|

Applications

| BASE VERSION Feeding of glass items washers Feeding of steam generators Feeding of thermostatic baths Feeding of ultra-pure water systems Autoclaves, boilers in general INDUSTRIAL USES |

demi VERSION Generalised laboratory uses Glass works rinsing Reagents preparation/dilution Colorimetric and qualitative analyses Feeding of thermostatic baths INDUSTRIAL USES |

demi2-TS VERSION HPLC chromatography Reagents preparation/dilution Colorimetric and qualitative analyses Spectro-phot. Analysis atomic absorption INDUSTRIAL USES As described for the DEMI version |

| quality standard | quality standard | quality standard |

|

purified water (usually El. Spec. Conductivity < 5-20 mcrS/cm) produced only with reverse osmosis system |

Conform ISO 3696: grade 3 Conform ASTM: type 4 Conform NCCLS: type 3 El. Spec. conduct. 25°C: 0.2-3 mcrS/cm El. Spec. resist. 25°C: 5 MOhm.cm |

Conform ISO 3696: grade 2 Conform ASTM: type 2 Conform NCCLS: type 2 El. Spec. conduct. 25°C: 0.1-1 mcrS/cm El. Spec. resist. 25°C: 10 MOhm.cm |

Quality, technology, versatility

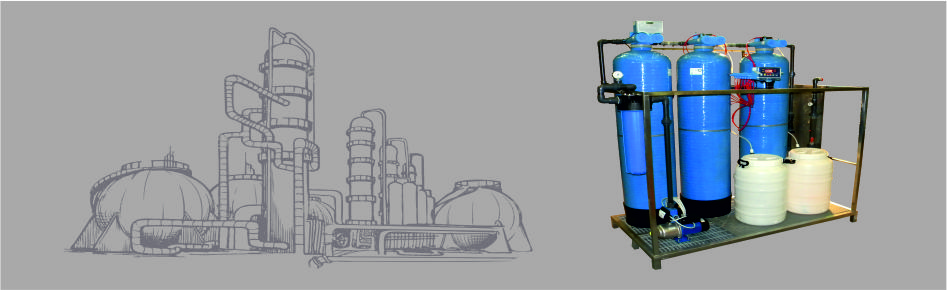

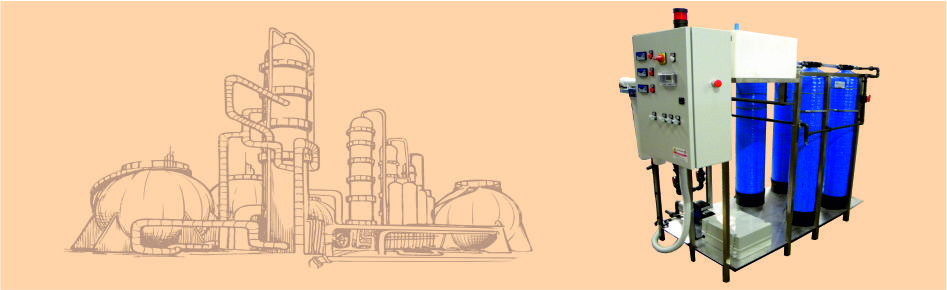

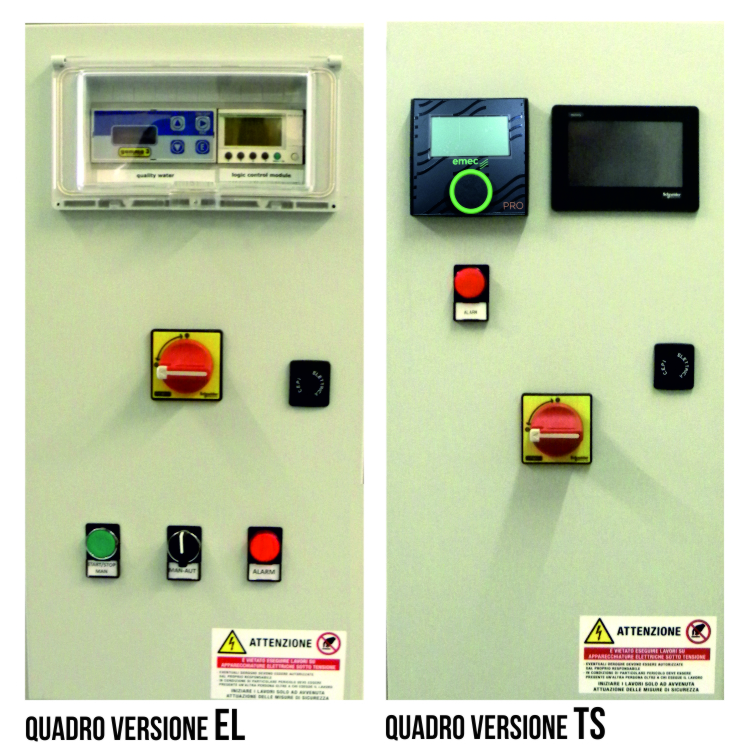

The RO 30 demineralizer is designed to produce deionized water with a high degree of purity for technical uses. The production costs of deionized water are reduced by up to 50% compared to normal resin deionizers, thanks to the use of high-quality reverse osmosis modules with high salt rejection (> 99%, operating pressure 10-16 bar). All the devices are mounted on a stainless steel frame and can be paneled on request. The water obtained can be considered excellent not only from the saline point of view but also from the organic aspect. RO 30 can adapt to the purity needs of the user, thanks to 3 versions with different degrees of purity and the possibility of regulating the conductivity of the output water as desired (optional). RO 30 is managed by an electronic control unit made in an IP 55 container, with PLC technology, both for the sequence and for the self-diagnosis of the operating phases, and is able to directly control all the functions of the appliance: management of the overpressure pump and solenoid valve, in-line detection of the conductivity of the water produced, with a digitally operated and readable conductivity meter, possibility of manual or automatic operation with 2 level sensors in the accumulation tank (minimum and maximum), or finally production in timed cycles (TS version only).

Alarms: water quality, machine block due to minimum network pressure, pump thermal block.

Operational characteristics of the electronic control panel |

|||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||

| TECHNICAL FEATURES | DIMENSIONS | |||

| - DAILY PRODUCTION | lt 300-400 | Lenght max | cm 53 | |

| - HOURLY PRODUCTION | lt/h 30 | Width max | cm 64 | |

| - Feed pressure | bar 2,5/4,5 | Height max | cm 142 | |

| - Temperature of water to be treated | °C 5-35 | |||

| - operative pressure RO elements | bar 14-15 |

|

||

| - hidraulic connection | IN: pipe PE 10/8 | |||

| OUT: pipe PE 6/4 | ||||

| DRAIN: pipe PE 8/6 | ||||

| - ELECTRIC POWER | V 220 AC | |||

| TECHINCAL SPECIFICATIONS WATER TO BE TREATED | |

| max permissible values | |

| - Total Hardness | °F 30 |

| - Iron | ppm 0,1 |

| - Manganese | ppm 0,005 |

| - Chlor | ppm 0,1 |

| - TDS | ppm 300 |

| - SDI | <5 |

| - Total bacteria | UFC/ml<5 |

|

It may still be necessary to dose liquid antiscal at the discretion of the manufacturer |

|

Optional Accessories

1 - Function Flow meter, managed directly by the PLC, to archieve precision fill. The external signal is provided by a pulse-counter teflon; starting the machine is in manual. The setting of the volume is easly adjustable with or without a pc.

print RO 30 EL-TS