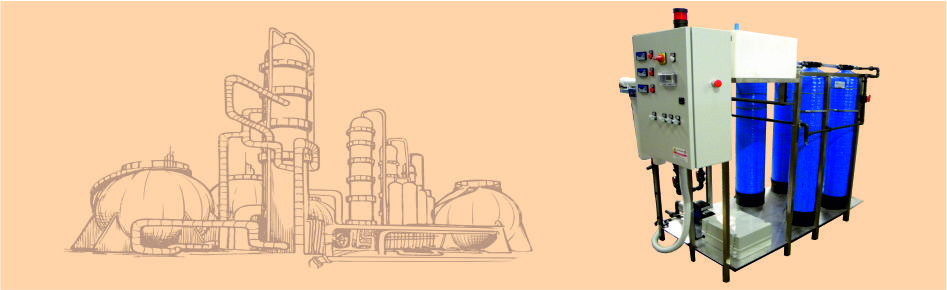

Reverse osmosis

A device for differential users needs

The RO CUBIC-S2 line provides the possibility to adapt each device to the individual user's needs.

Indeed RO CUBIC-S2 is controlled by an electronic PLC control unit with a brand new dedicated software and can manage all active functions and control of the machine (it is therefore possible by the user to request specific changes that are better adapted to their requirements) and a regulator of the quality of water supplied depending on the intended use.

2 models

- RO 15 CUBIC-S2 15 lt/h

- RO 30 CUBIC-S2 30 lt/h

4 stages of purification

- anti-sediment microfilter

- reverse osmosis whit booster pump

- UV ray sterilizer (optional)

- anti-bacteria microfilter 0,2 micron (optional)

4 operating modes

- ON/OFF manual

- ON/OFF automatic with 2 sensor level in the storage tank (min/max)

- ON manual and OFF automatic (with sensor level in the storage tank)

- ON manual and OFF with flow-meter (opzional and with volume predeterminated)

A control panel easily and efficiently

The RO CUBIC-S2 line is equipped with an efficient control panel in the front and easily viewable by the operator.

| - | 2 manometers (pressure feed water, operating pressure), steel case and glycerine |

| - | Digital conductivity meter for monitoring the quality of water supplied; wide LCD diplay, |

| possibility to remote the measured value with the output 4-20 mA configurable | |

| - | PLC control unit with LCD display |

| - | Cumulative fault warning light (low pressure, replacement pre filter, water quality, |

| replacing anti bacterial filter when present. |

| TECHNICAL FEATURES | REQUIREMENTS OF FEED WATER | |||

| - MIN. feed pressure | bar 1,5 | - TDS | max 500 ppm | |

| - MAX. feed pressure | bar 4,0 | - HD | max 30 °F | |

| - MAX. operative pressure | bar 8,0 | - Ferro | max 100 ppb | |

| - range of temp. water to be treated °C | 5-35 | - Manganese | max 5 ppb | |

| - hydraulic connections | IN pipe PE 10 | - cloro | max 0,1 ppm | |

| OUT pipe PE 6 | - Batteri tot. | max 5 UFC/ml | ||

| DRAIN pipe PE 6 | - SDI | < 5 | ||

| - electric power | V 220 ac | |||

| OPTIONALS | DIMENSIONS | |||

| Storage tank in PE-HD | lt. 25, 50, 100, 200 | Lenght | 65 cm | |

| Group of repressurization BOOSTER | Width | 37 cm | ||

| UV ray sterilizer | Height | 60 cm | ||

| Anti-bacteria filter 0,2 micron | ||||

| flow-meter | weight of the pack | 30 kg | ||

print RO-CUBIC-S2

|

|

|

|

|